An Introduction to MEMS Microphone Arrays

MEMS, or Micro-Electro-Mechanical Systems are tiny devices that combine electrical and mechanical parts on a microscopic level ranging from a few micrometers to millimeters. These systems use sensors, actuators, and microelectronics to create small, complex devices through microfabrication technology. At the heart of MEMS technology is its capability to integrate mechanical elements like gears, springs, and hinges with electronic circuits on a single silicon chip. Because of this integration, MEMS devices can sense, control, and actuate on a micro scale while communicating on a macro scale. This article explores the main role of MEMS in various fields, from consumer electronics to healthcare. MEMS devices changed traditional technologies with innovations like MEMS microphone arrays used in cars and telecom systems.

Catalog

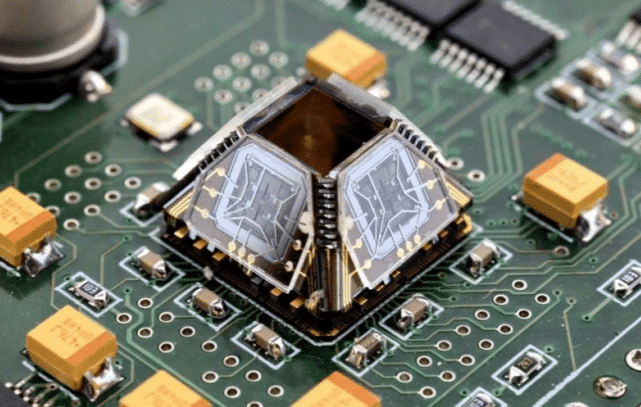

Figure 1: MEMS (Microelectromechanical Systems) Microphone Arrays

Role of MEMS in Modern Technology

MEMS technology is demand in many industries because it's flexible, small, energy-efficient, and cost-effective. Here's how MEMS are used in modern technology:

Consumer Electronics

MEMS are useful in consumer electronics, enabling functions like motion sensing and image stabilization in devices such as smartphones, tablets, and gaming consoles. Common MEMS devices in this field include gyroscopes and accelerometers.

Automotive Industry

In the automotive sector, MEMS enhance both safety and functionality. They are used in airbag sensors, tire pressure monitoring systems, and vehicle stability control systems, contributing to improved safety and performance.

Healthcare

MEMS technology is transforming medical devices. Examples include lab-on-a-chip devices for diagnostics, implantable drug delivery systems, and advanced surgical tools that enable minimally invasive procedures.

Industrial Applications

In industrial environments, MEMS sensors monitor conditions like temperature, pressure, and vibration. This monitoring supports predictive maintenance and boosts system efficiency.

Telecommunications

MEMS improve communication systems by enhancing devices such as optical switches and variable capacitors, good for managing signal routing and network performance.

Environmental Monitoring

MEMS-based sensors monitor environmental conditions, including air and water quality, and detect hazardous gases. Their small size and efficiency make them suitable for deployment in diverse and often remote locations.

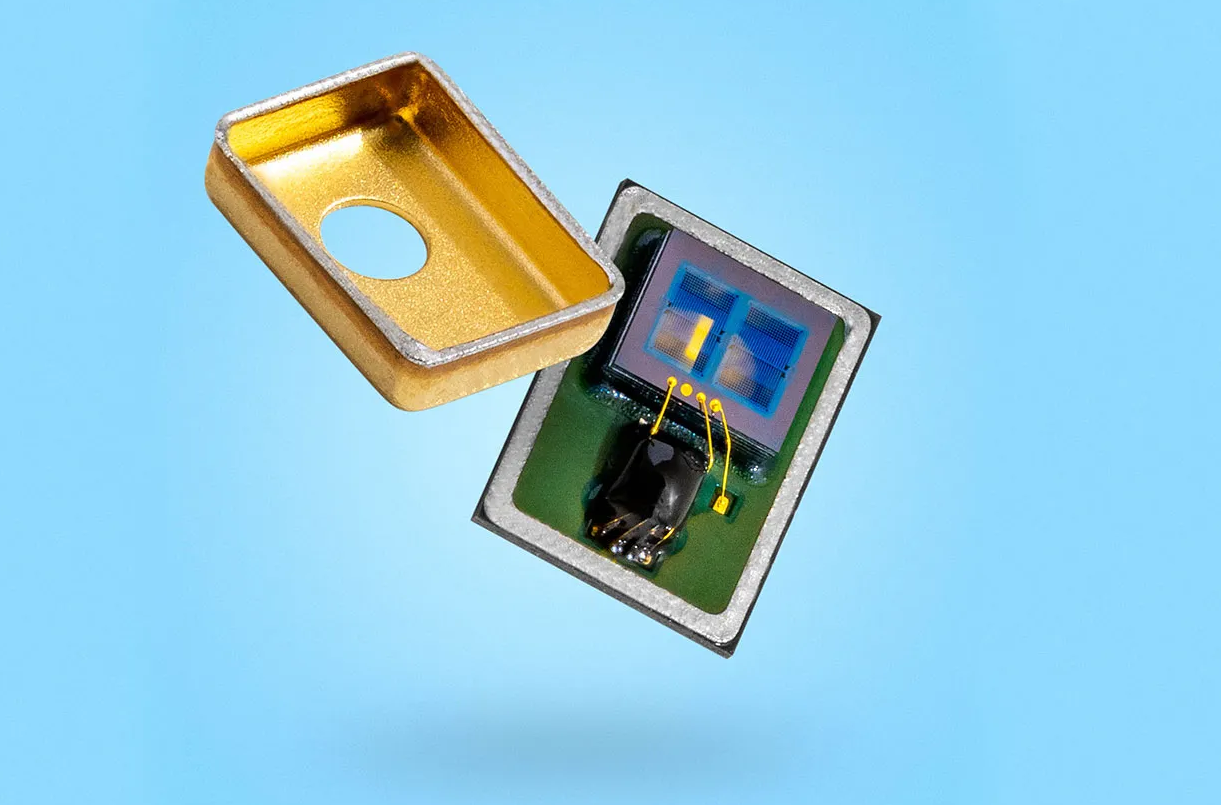

Figure 2: MEMS Device

Composition and Operation of MEMS Microphone Arrays

Below, we delve into the structure, sound processing methods, and signal combination techniques of MEMS microphone arrays.

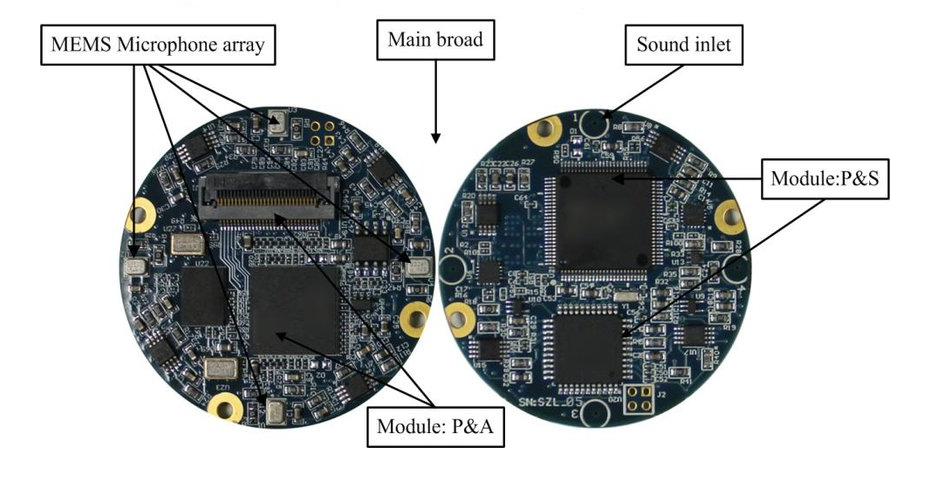

Description of the Array Structure

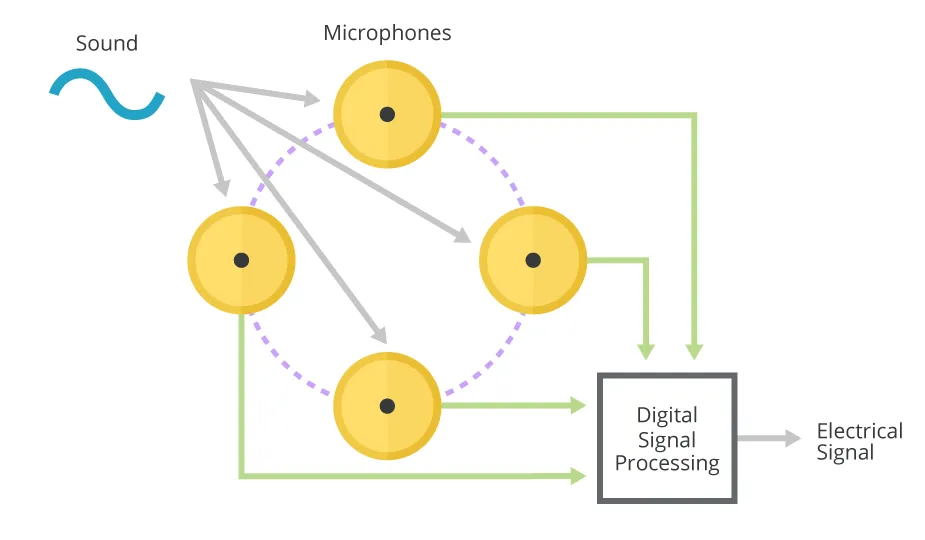

MEMS microphone arrays consist of multiple microphones positioned to work together. Each microphone is a tiny device with mechanical and electronic components, made using semiconductor manufacturing techniques. These microphones convert sound into electrical signals.

The array's configuration can vary, arranged in patterns like linear, circular, or planar formations. This setup influences the array's directionality and sensitivity, enabling it to capture sound from specific directions while ignoring others. The combined electrical output from these arrays is processed to form a single, high-quality audio signal.

Figure 3: MEMS Microphone Array System

How Arrays Process Sound

Sound processing in MEMS microphone arrays involves amplifying, delaying, and filtering the signals from individual microphones. Each step serves a specific purpose:

• Amplification boosts the weak signals from the microphones, making them strong enough for further processing.

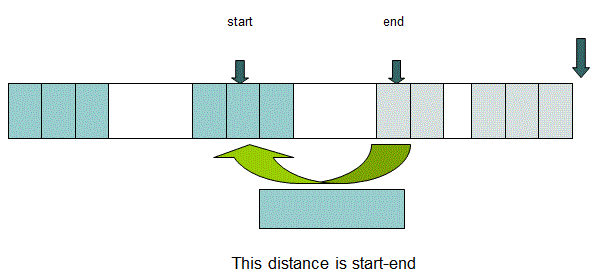

• Delaying synchronizes the sounds captured by different microphones at different times due to their physical separation. This synchronization good for accurate sound localization and beamforming.

• Filtering enhances certain frequencies while suppressing others, depending on the desired output. For example, it can remove high-frequency noise or boost frequencies important for speech clarity.

Figure 4: Arrays and Digital Sound

The Technical Process of Combining Signals

Combining signals in MEMS microphone arrays is a sophisticated process aimed at enhancing desired sounds while reducing background noise, known as beamforming. Beamforming uses the microphone arrangement and the differential timing (delay) of sound waves to focus the array's sensitivity on the sound source of interest, minimizing interference from unwanted noise.

This process involves calculating weights for each microphone's output, determining how much each signal should contribute to the final output. The weights adjust based on the sound waves' direction and the acoustic environment. Combining these weighted signals, the array creates a directional focus that enhances sound capture from specific directions while reducing interference.

Advanced signal processing techniques like adaptive filtering dynamically adjust processing parameters in response to changes in the sound environment. This adaptability allows MEMS microphone arrays to maintain optimal performance in various settings, from quiet studios to noisy outdoor environments.

Figure 5: MEMS Microphone Arrays

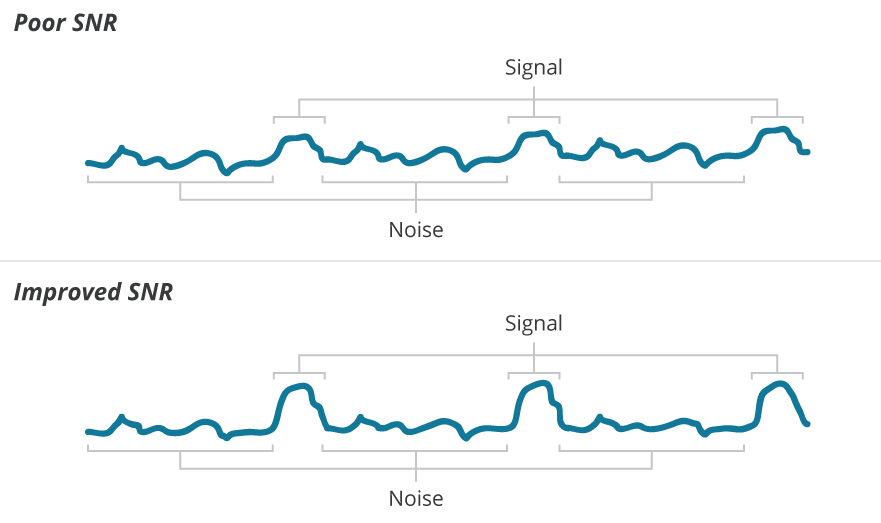

Importance of Signal-to-Noise Ratio (SNR)

Signal-to-Noise Ratio (SNR) is an important measure in audio technology. It compares the level of the desired signal to the level of background noise, expressed in decibels (dB). A higher SNR means a clearer audio signal with less noise, while a lower SNR indicates more background noise, which degrades audio quality.

SNR used for many audio devices, from smartphones and headphones to professional recording equipment. In high-quality audio systems, a high SNR means the audio output is very close to the original recording, with minimal background noise. This is useful in recording studios because small noises can greatly affect audio quality.

In communication systems, SNR require for clarity. For example, in a noisy environment, a device with a poor SNR will produce unclear audio, making it hard for users to understand each other. Therefore, maintaining a high SNR is a main goal in designing and developing audio technologies.

Figure 6: Signal-to-Noise Ratio (SNR)

How MEMS Microphone Arrays Improve SNR by Reducing Unwanted Noise

Beamforming

MEMS microphone arrays enhance SNR through beamforming. This technique processes signals from multiple microphones to create a focused, directional response. By capturing sound from a specific direction and minimizing noise from other directions, beamforming is effective in settings where the sound source is fixed and known, like in smart speakers and conference systems.

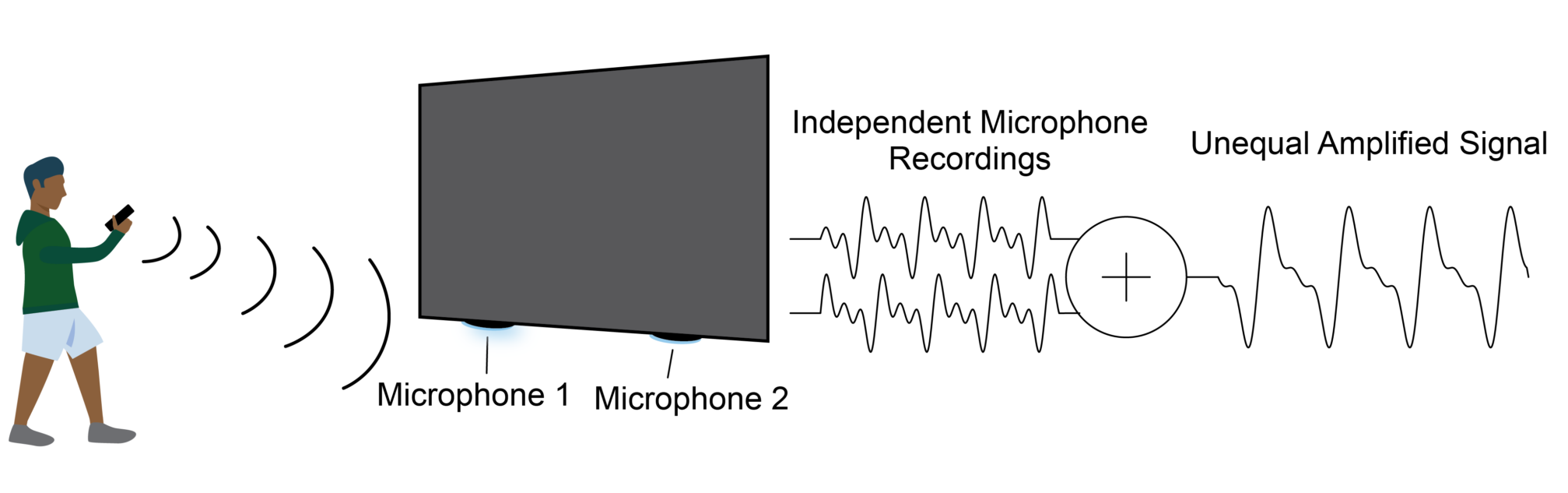

Noise Cancellation

Another method for improving SNR is noise cancellation. By comparing audio signals from different microphones within the array, the system can detect and nullify unwanted noise, thereby enhancing the clarity of the desired signal. This feature is useful in consumer electronics often used in noisy public spaces.

Spatial Filtering

MEMS microphone arrays also excel in spatial filtering, which isolates sounds from various locations. This not only reduces background noise but also improves overall audio capture quality. Such capabilities make MEMS arrays ideal for complex acoustic environments.

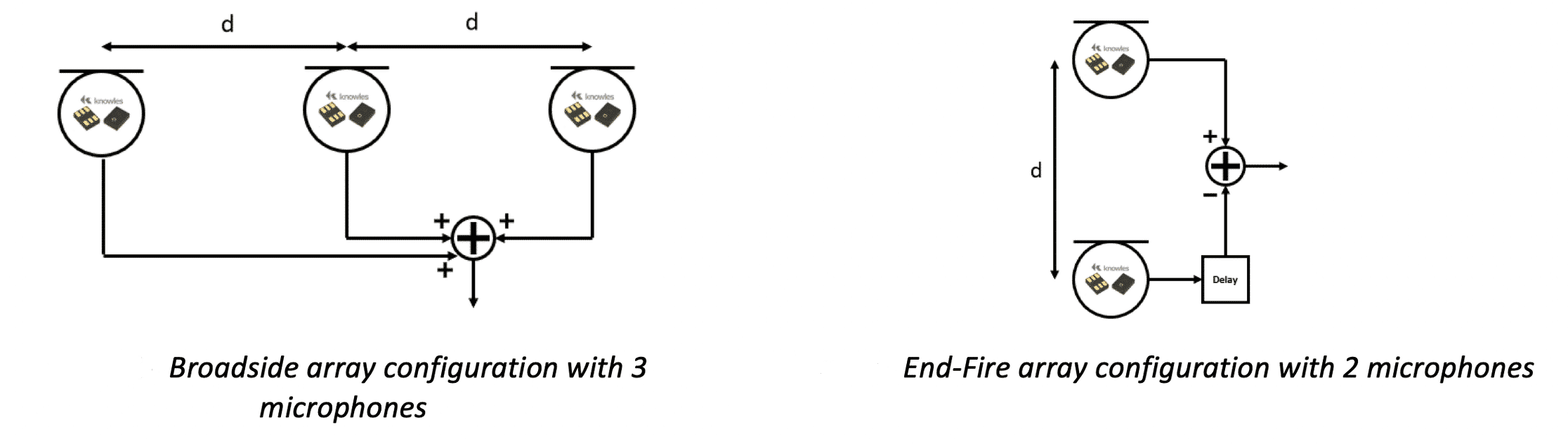

Broadside Microphone Arrays

Broadside microphone arrays are arranged in one or two dimensions, perpendicular to the sound source. This setup is effective in environments with predictable sound directions, allowing the system to focus on sounds from the front while ignoring lateral noise. The physical arrangement ensures that all microphones receive sound from the intended direction simultaneously, leading to constructive signal summation. Sounds arriving from other directions, however, experience phase discrepancies due to different arrival times, resulting in weaker summation and reduced output. This configuration is ideal for devices like computer monitors or TV screens, enhancing the auditory experience by focusing on sounds directly from the display area.

Figure 7: Broadside Microphone Arrays

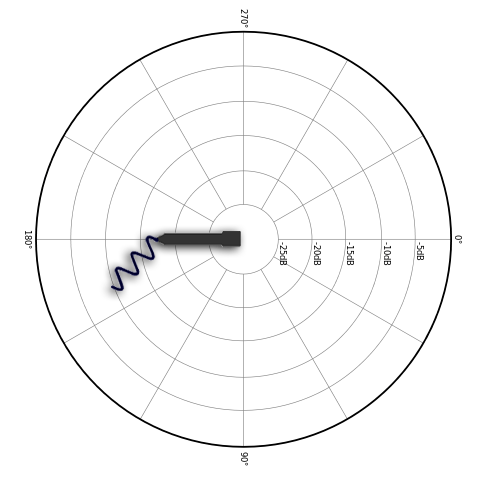

Endfire Microphone Arrays

Endfire microphone arrays position microphones linearly along the direction of the sound. This setup takes advantage of the natural time delays in sound propagation, with each microphone capturing the sound at slightly delayed intervals. These delays are electronically adjusted to synchronize the signals, enhancing the summation of desired sounds. Endfire arrays are excellent at isolating sounds from the front while reducing noises from other directions, including the rear. This directional focus makes them suitable for handheld devices like microphones used in public speaking or performances, where they can target specific sound sources and isolate them from ambient noise.

Figure 8: Broadside Microphone Arrays vs. Endfire Microphone Arrays

Working Principles of MEMS Microphone Arrays

MEMS (Micro-Electro-Mechanical Systems) microphone arrays are advanced devices combining microfabrication technology with sound engineering to capture and process audio with high precision. These arrays operate based on several core functionalities: sound capture, signal processing, and noise reduction.

Sound Capture Through Multiple Microphones

MEMS microphone arrays use multiple spatially distributed microphones to sample the acoustic environment. Each microphone converts sound waves into electrical signals, allowing the system to gather audio from various directions. This setup enhances the array's accuracy in detecting the origin and characteristics of sounds. The spatial distribution require to capture a broader sound field tasks like sound localization and beamforming. Beamforming directs the array's sensitivity towards a specific sound source while suppressing others.

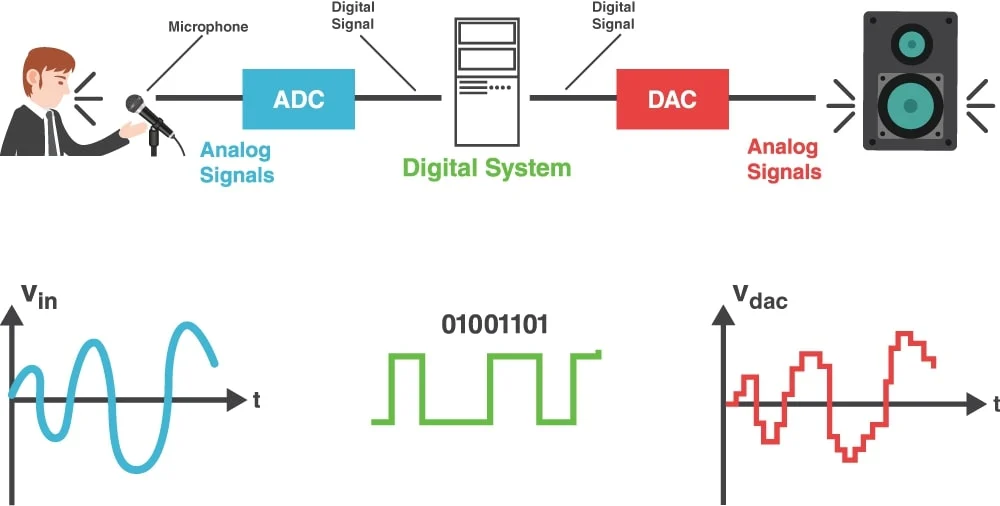

Digital Signal Processing (DSP)

After capturing sound, the electrical signals from each microphone are processed by a DSP system. This system is the computational center of MEMS microphone arrays, where raw data is analyzed. DSP algorithms synthesize signals from multiple microphones to create a cohesive sound map. Time-stamping each signal, the system can accurately determine the direction and trajectory of the sound through space.

Figure 9: Digital Signal Processing Block Diagram

Noise Filtering and Sound Enhancement

The DSP also enhances audio quality by filtering out background noise and clarifying the desired sound. Techniques like noise suppression, echo cancellation, and gain control are employed to improve audio fidelity. These processes are best for applications requiring clear sound reproduction, such as teleconferencing systems, hearing aids, and smartphone voice assistants.

MEMS Microphones Types

Figure 10: MEMS Omnidirectional Microphone

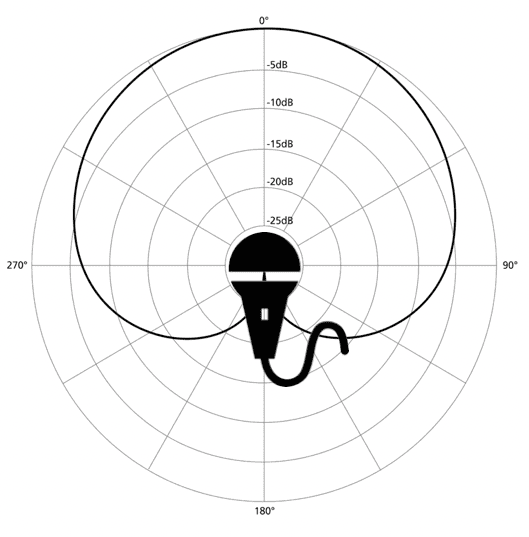

Omnidirectional Microphone

MEMS omnidirectional microphones capture sound uniformly from all directions. This sets them apart from directional microphones, which focus on sound from specific directions. MEMS omnidirectional microphones use tiny diaphragms made with MEMS technology. These diaphragms detect sound waves from any direction and making the microphones highly adaptable. Their small size and consistent performance allow for easy integration into various devices.

These microphones excel in settings where sound sources move or come from multiple directions. For example, in a conference room, people can speak from any direction around the table. The omnidirectional microphone ensures clear voice capture, enhancing communication and recording.

Smart home devices, like voice-activated assistants, must pick up commands from anywhere in the room. Similarly, security systems rely on these microphones to detect sounds that trigger alerts, benefiting from their comprehensive sound capture.

Figure 11: MEMS Directional Microphone

Directional Microphone

Micro-Electro-Mechanical Systems (MEMS) directional microphones are important for improving audio clarity by focusing on sounds from specific directions and minimizing unwanted noise. This technology uses an array of tiny microphones that work together to enhance sensitivity toward a targeted area. This approach is useful in telecommunications and hearing aids.

In telecommunications, MEMS directional microphones isolate and amplify sound from particular directions, ensuring clear conversations despite ambient noise. This is functional in noisy places like busy streets or crowded offices. Focusing on the speaker's voice and cutting out background noise, these microphones offer clearer and more understandable audio, improving the user experience.

Advanced hearing aids use these microphones to focus on the primary sound source the user is facing, adapting to changes in the auditory environment to maintain optimal performance.

MEMS directional microphones also incorporate sophisticated signal processing algorithms. These algorithms analyze sound from various angles and selectively amplify sound waves from the desired direction. This advanced technology not only enhances microphone performance but also allows for integration into smaller devices good for miniaturized gadgets like smartphones and hearing aids.

Advantages

Both omnidirectional and directional MEMS microphones offer unique benefits for different situations. Directional microphones excel in noisy environments by isolating the main sound source, enhancing hearing aid performance. Omnidirectional microphones are better for quiet settings, capturing sound from multiple directions, making them suitable for monitoring systems. Modern hearing aids often combine both types, allowing for manual or automatic adjustments to adapt to varying ambient sounds.

Features of Digital MEMS Microphones

Digital MEMS microphones deliver data in a ½ cycle Pulse-Density Modulation (PDM) format, requiring synchronization between a clock input (CLK) and a data output (DATA) line. A single DATA line is shared between two microphones, designated as "left" or "right" by setting the L/R input pin to Vdd or ground. These devices are powered by either 1.8V or 3.3V supplies.

In operation, the "left" microphone writes data on the rising edge of the CLK, and the "right" on the falling edge. If the right microphone fails or is absent, the left microphone continues to write data on the rising edge and switches to high-impedance on the falling edges. This causes the DATA line to reflect only the left microphone's output, resulting in an error as the DSP receives identical data for both channels. To avoid these problems, we need thorough testing. The clock frequency, ranging from a few hundred kHz to 3 MHz, affects power consumption and audio quality. Short cable distances help to maintain digital signal integrity and minimize losses due to long, high-capacitance cables.

The Multiple MEMS Microphones

Using multiple MEMS microphones in devices improves their audio capturing capabilities. Several microphones working together enhance the signal-to-noise ratio (SNR), for maintaining high audio quality in noisy environments like cars or during mobile calls. Multi-microphone setups support advanced features like beamforming.

Integrating multiple MEMS microphones also brings testing and validation challenges. Engineers must perform multichannel measurements to ensure phase alignment and synchronization across the microphone array. To improve audio output, DSP algorithms need precise testing. Strict processes and advanced testing equipment ensure these systems work reliably and produce high-quality sound.

Conclusion

MEMS technology is a main part of modern innovations, improving the quality and function of many systems. For example, MEMS microphones enhance audio in consumer electronics and boost safety in cars. These devices improve signal clarity, deliver high-quality sound, and cut down on noise. The creation of digital MEMS microphones shows how this technology is evolving to meet the needs of today's devices with precision, efficiency, and reliability. As MEMS technology keeps advancing, it will continue to be important in making both current and future technologies better.

Frequently Asked Questions [FAQ]

1. Is microphone array an actual microphone?

Yes, a microphone array is indeed a collection of actual microphones. It consists of multiple microphone units placed to capture sound from different directions. This configuration allows the array to perform complex audio processing tasks like noise reduction and directionality, enhancing sound capture quality compared to a single microphone.

2. What is the difference between stereo mix and microphone array?

The terms "stereo mix" and "microphone array" refer to different aspects of sound handling. A stereo mix is a feature on a computer's sound card that combines all audio inputs and outputs into a single stereo track, allowing you to record or stream the combined audio from various sources simultaneously. On the other hand, a microphone array involves multiple microphones working together to record audio, often used to capture spatial sound information and improve sound quality by isolating the audio source from background noise.

3. Is MEMS microphone analog or digital?

MEMS (MicroElectroMechanical Systems) microphones can be either analog or digital. The type depends on the output format of the audio signal they produce. Analog MEMS microphones output audio signals as analog waves, requiring additional circuitry for conversion to digital signals. Digital MEMS microphones, however, include an integrated circuit that converts sound directly into a digital signal, simplifying connectivity with digital devices.

4. How do I test my MEMS microphone?

Testing a MEMS microphone involves several steps to ensure it is functioning correctly:

Connectivity Check: First, ensure the microphone is properly connected to your testing device (like a computer or analyzer).

Visual Inspection: Check for any physical damage that could affect performance.

Sound Test: Use a standard sound source or speak into the microphone to check for clarity and volume. Software tools or dedicated audio testing devices can help analyze the sound quality and detect issues like distortion or noise.

Functional Tests: Use diagnostic software to run functional tests that check the microphone's response across different frequencies and sound levels.

5. What is the voltage of a MEMS microphone?

The operating voltage of MEMS microphones ranges between 1.5 to 3.6 volts, depending on the specific model and manufacturer. It's important to refer to the technical datasheet of the specific MEMS microphone model you are using to confirm the correct operating voltage and ensure it matches your application's power supply specifications.