LTST-C191KRKT SMD LED: Specifications and Datasheet

This article delves into the LTST-C191KRKT red LED chip, renowned for its compact size and broad viewing angle, designed to meet the demands of modern electronic devices. With an efficient energy profile and high luminosity, this LED exemplifies the industry's push towards components that offer power savings while enhancing device performance and aesthetic appeal.Catalog

What is the LTST-C191KRKT?

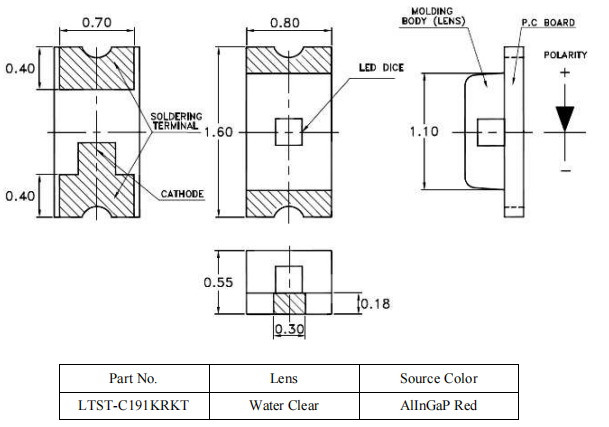

The LTST-C191KRKT LED chip, crafted for streamlined surface-mount assembly, meets the pressing demands of space-limited environments. Its slender design finds favor in electronic devices where space is scarce. The dimensions of this LED not only offer adaptability across multiple applications but ensure smooth integration into densely packed circuit board layouts common in cutting-edge technology.

In the swiftly transforming world of compact gadgets, incorporating components that sustain efficiency while conserving space is a persistent challenge. The thin profile of the LTST-C191KRKT adeptly supports these needs. For example, in wearable tech, where size and battery life hold substantial weight, these LEDs deliver luminous efficiency without sacrificing aesthetics or comfort. Industry often confront the task of optimizing battery life while preserving performance, with this LED emerging as a reliable ally.

Designed for straightforward handling during production, the LTST-C191KRKT minimizes error potential and ensures uniformity across production batches. Such attributes play a role in sustaining consistent manufacturing quality. In the field, utilizing components known for stability and performance aids in minimizing downtime and fosters consistent operation across devices.

The application of LEDs like the LTST-C191KRKT highlights how thoughtful component choices can drive progress in device miniaturization. By emphasizing the sophistication and functionality of these components, you can elevate the benchmarks for sleek and energy-efficient device creation. In sum, the strategic decision to implement ultra-thin profile LEDs not only addresses space-related challenges but also aligns with broader trends in sustainable and innovative electronic design.

LTST-C191KRKT Equivalents and Alternatives

|

Part Number |

Description |

Manufacturer |

|

SML-311UTOPTEOELECTRONICS |

Single Color LED, Red, Colorless Transparent, 1.2mm, 1.60

x 0.80 mm, 0.80 mm HEIGHT, ROHS COMPLIANT PACKAGE-2 |

ROHM Semiconductor |

|

LNJ808R88RAOPTOELECTRONICS |

Single Color LED, Orange, Diffused Red, 1.1mm, SURFACE

MOUNT PACKAGE-2 |

Panasonic Electronic Components |

|

LT1ZJ67AOPTOELECTRONICS |

Single Color LED, Orange, Milky Diffused, 1.2mm |

Sharp Corp |

|

LTST-C190KRKTOPTOELECTRONICS |

Single Color LED, Red, Water Clear, 1.1mm, GREEN, PLASTIC

PACKAGE-2 |

Lite-On Semiconductor Corporation |

|

LTST-C191KRKT |

Colorless, 0603 (1608 Metric), 2, 54 mcd, Rectangle with

Flat Top, 30 mA, 20mA, 130° |

Lite-On Inc. |

|

APG1608SURKC/T |

Colorless, 1206 (3216 Metric), 2, 6 mcd, Rectangle with

Flat Top, 20 mA, 20mA, 160° |

Kingbright |

|

SML-LX0805IC-TR |

Colorless, 0805 (2012 Metric), 2, 9 mcd, Rectangle with

Flat Top, 20 mA, 20mA, 140° |

Lumex Opto/Components Inc. |

|

SML-LX1206IC-TR |

Colorless, 0603 (1608 Metric), 2, 110 mcd, Rectangle with

Flat Top, 20 mA, -, 120° |

Lumex Opto/Components Inc. |

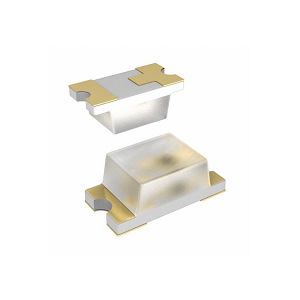

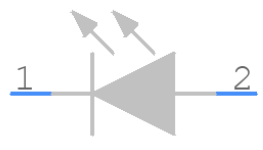

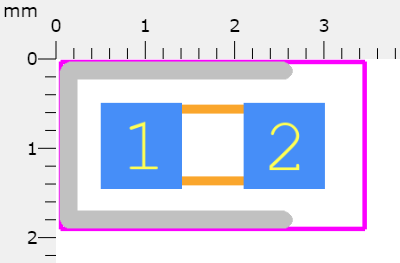

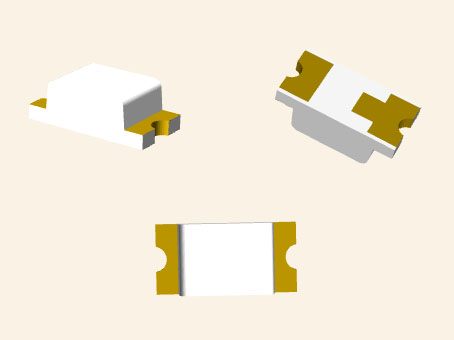

LTST-C191KRKT Symbol, Footprint, and CAD Model

Features of the LTST-C191KRKT

Compliance and Sleek Design

The LED aligns with ROHS standards, its role in supporting environmental well-being amid growing regulatory demands. Its exceptionally thin design is fitting for modern contexts where space constraints challenge creativity, such as in the intimate embrace of wearable technology or the sleek sophistication of compact electronics.

Cutting-Edge Technology

Through the use of ultra-bright AlInGaP technology, this LED brings forth remarkable levels of brightness coupled with commendable energy efficiency. This advancement aids in conserving energy while delivering powerful illumination, aligning with industry goals to boost device sustainability.

Efficiency in Packaging and Assembly

Packaged within 8mm tape, it is compatible with automated placement systems, thus enhancing both the precision and swift pace of large-scale manufacturing. Its adeptness at infrared reflow soldering further simplifies the manufacturing process, mirroring the industry's movement towards greater automation.

The integration of automated systems not only advances efficiency but also minimizes error, offering a clear advantage to companies pursuing uniformity in mass production. When viewed in a broader industrial context, these attributes collectively bolster the LED’s versatility across a range of applications, from vehicle lighting to complex display systems.

LTST-C191KRKT Specifications

|

Type |

Parameter |

|

Factory Lead Time |

12 Weeks |

|

Mounting Type |

Surface Mount |

|

Number of Pins |

2 |

|

Number of Elements |

1 |

|

Packaging |

Cut Tape (CT) |

|

Size Dimension |

1.60mm L x 0.80mm W |

|

Pbfree Code |

yes |

|

Moisture Sensitivity Level (MSL) |

2A (4 Weeks) |

|

Terminal Finish |

Tin (Sn) |

|

Min Operating Temperature |

-55°C |

|

Additional Feature |

IC COMPATIBLE |

|

Packing Method |

TAPE AND REEL - 7 |

|

Depth |

800μm |

|

Case Code (Imperial) |

603 |

|

Voltage |

2V |

|

Power Dissipation |

75mW |

|

Optoelectronic Device Type |

SINGLE COLOR LED |

|

Current - Test |

20mA |

|

Lens Size |

1.10mm x 0.80mm |

|

Lens Transparency |

Clear |

|

Lens Color |

Colorless |

|

Height |

550μm |

|

RoHS Status |

RoHS Compliant |

|

Mount |

Surface Mount |

|

Package / Case |

0603 (1608 Metric) |

|

Shape |

RECTANGULAR |

|

Wavelength-dominant |

631nm |

|

Published |

2007 |

|

JESD-609 Code |

e3 |

|

Part Status |

Active |

|

Number of Terminations |

2 |

|

Max Operating Temperature |

85°C |

|

Color |

Red |

|

Power Rating |

75mW |

|

Number of Functions |

1 |

|

Case Code (Metric) |

1608 |

|

Configuration |

Standard |

|

Current |

2A |

|

Viewing Angle |

130° |

|

Forward Current |

30mA |

|

Lens Style |

Rectangle with Flat Top |

|

Luminous Intensity |

54 mcd |

|

Wavelength - Peak |

639nm |

|

Reverse Voltage |

5V |

|

Radiation Hardening |

No |

|

Lead Free |

Lead Free |

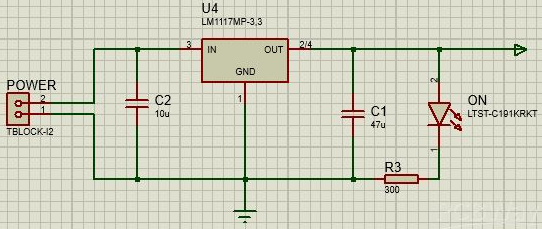

Creating an ESP32 Breakout with LTST-C191KRKT

To smoothly integrate the LTST-C191KRKT LED with an ESP32 board, a deep understanding of the LED's specifications and the microcontroller's capabilities is needed. Analyzing the forward voltage and current ratings of the LED can lead to refined performance and extended longevity. Attention to these parameters ensures a harmonious interaction within microcontroller circuits, leading to optimal design outcomes. Incorporating a current-limiting resistor becomes a natural part of the drive method for LEDs. This step curtails excessive current, offering consistent brightness. Calculate the resistor's value by considering the difference between the ESP32's output voltage and the LED's forward voltage, divided by the target current. Such mathematical planning remains a reliable practice, fostering predictable results in electronic design.

Drive Method of LTST-C191KRKT

In scenarios like displays and indicators, achieving consistent brightness in LED arrays contributes to visual harmony and accurate information dissemination. Fluctuations in brightness can cause misunderstandings and diminish the effectiveness of communication. By managing current variations across LEDs, a series resistor plays a guiding role. This element keeps the current stable amidst voltage changes, promoting even luminance. It absorbs surplus voltage, preventing LEDs from excessive current draw that could lead to overheating or erratic brightness. Incorporating a series resistor involves determining the proper resistance that suits an LED array's unique requirements. Experimenting with various resistor values is advisable to fine-tune brightness levels, thus avoiding potential issues like excessive power consumption or reduced efficiency.

Application of LTST-C191KRKT

Electronics and Devices

The integration of advanced electronics into daily life reshapes our interaction with technology, sparking curiosity and desire. From smartphones to smart homes, electronic components must balance efficiency with sustainability. Designing devices that captivate while supporting environmental goals remains a fascinating challenge. Utilizing innovative materials and technologies can greatly enhance device performance and durability.

Aviation Systems

Aviation systems are marked by a demand for precision guided by a legacy of achievement. Aircraft technology must endure harsh conditions while adhering to strict safety standards. Others rely on extensive data and personal insights to develop avionics systems that function optimally. Advancements in materials used in aircraft electronics promise strides in fuel efficiency and safety.

Transportation and Traffic Management

Sophisticated technologies lie at the heart of efficient transportation systems, driven by the goal to enhance safety. Automated rail networks and intelligent urban traffic systems require adaptable and robust tech to function smoothly. Emerging smart infrastructure trends focus on integrating data analytics to transform traffic flow, easing congestion and improving commuter satisfaction.

Medical Devices

In healthcare, medical devices play roles, invoking a deep sense of responsibility and care. These range from diagnostic tools to therapeutic equipment, demanding unparalleled precision and reliability. Innovations in miniaturization and connectivity are redefining patient treatment. Crafting devices that are both friendly and effective involves intricate design and exhaustive testing, all while nurturing the commitment to better healthcare outcomes.

Safety and Monitoring Equipment

Industries reliant on safety equipment necessitate exceptional reliability and resilience, sparking a need to protect and preserve. Whether in construction, manufacturing, or emergency response, advanced monitoring systems offer oversight. Designing these systems mandates an understanding of potential hazards and the flexibility to address emerging threats, providing comprehensive security and risk management.

Storage of LTST-C191KRKT

Store in a setting where the temperature does not exceed 30°C, and maintain a relative humidity of 60%. Such conditions support material longevity and reliability, reducing the risk of degradation that might impair functionality. Research reveals that consistent temperatures help preserve material integrity. This stability reduces thermal expansion and contraction effects, which can cause microstructural fatigue.

Control humidity precisely at 60% to avoid moisture absorption, for hygroscopic materials. Utilizing desiccant packs or humidity-controlled storage can be effective in sustaining these levels. Unopened original packaging provides protection from environmental exposure. If disrupted for more than 672 hours, a systematic method is necessary to regain material readiness. A 60°C bake for 20 hours should be performed prior to soldering processes. This step ensures any absorbed moisture is eliminated, supporting effective solder adhesion and reliability.

Mitigating Electrostatic Discharge (ESD) Risks

Electrostatic discharge introduces challenges to LED components, which require nuanced approaches to preserve their performance and lifespan. The delicate nature of LED microstructures makes them susceptible to ESD, potentially causing instant failure or gradual degradation. Employing well-rounded protection strategies is use to counteract these vulnerabilities.

Incorporating tools like anti-static mats, wrist straps, and conductive clothing can reduce static electricity. Grounding methods are instrumental in maintaining a static-free environment: Anti-static accessories constitute the primary defense by neutralizing charges on both personnel and equipment, thereby limiting potential damage. Grounding entails uniting all conductive elements to a standard earth point, efficiently dispersing charge buildup. Ion blowers are invaluable in controlling static during LED handling by releasing balanced streams of ions to discharge surfaces.

LTST-C191KRKT Packaging

LTST-C191KRKT Manufacturer Information

Founded in 1975, Lite-On has established a remarkable presence in the optoelectronics sector, especially when it comes to their adept manufacturing of both visible and infrared technologies. They harbor a steadfast dedication to pushing inventive boundaries, grounded firmly in a keen emphasis on research and development. This commitment has allowed them to navigate the waves of technological progress with impressive agility. Over the years, Lite-On has nimbly shifted with the tides of market evolution, consistently securing a strong market position through relentless innovation and enhanced efficiency. Their enduring journey mirrors an innate adaptability in a world where technology constantly evolves. A compelling perspective surfaces when examining Lite-On's strategic acumen in addressing global supply chain disruptions and market unpredictability. Their knack for transforming challenges into opportunities showcases an intuitive grasp of market dynamics. With the rapid pace of digital transformation, their thoughtful integration of data analytics and AI into both production and service highlights a standard for industry peers. This fusion of tradition with innovation within their corporate ethos embodies an enlightening voyage towards sustainable and inclusive advancement.

Datasheet PDF

LTST-C191KRKT Datasheets:

Cylindrical Battery Holders.pdf

Frequently Asked Questions [FAQ]

1. What mean SMD LED?

Surface-mounted diodes mark a leap in LED innovation when contrasted with traditional dual inline package LEDs. Their compact form and surface mounting capabilities offer enhanced design possibilities and improved performance, sparking creativity in design applications.

2. Are SMD LEDs any good?

SMD LEDs are celebrated for their remarkable efficiency, delivering more lumens per watt than chip-on-board LEDs. Their efficiency makes them popular in scenarios demanding sustained brightness and energy conservation. Many have observed that, whether at home or in business settings, opting for SMD LEDs often leads to noticeable reductions in electricity expenses and consistent superior performance.

3. What are SMD LEDs used for?

As a staple in modern lighting, SMD LEDs are versatile. They feature prominently in household illumination, industrial setups, automotive lighting, and electronic displays. Their steady light output and range of colors enrich contemporary lighting aesthetics.

4. What is LTST-C191KRKT?

The LTST-C191KRKT, a compact red SMD LED, stands out with its 54 mcd brightness. Serving as a potent light source, it is favored in specialized areas where precise lighting intensity and hue are needed. Its diminutive design makes it suitable for space-limited contexts.

5. What company offers SMD LED bulbs in microscopic sizes and unique configurations?

Lite-On stands out as a supplier of advanced SMD LEDs, recognized for their leadership in LED technology. The trust in their products stems from consistent reliability and robust performance.

6. What type of products can SMD LED lamps be used in?

The adaptability of SMD LEDs sees their integration into a broad spectrum of electronic devices. From gadgets to advanced industrial lighting, they meet the evolving demands for energy efficiency and superior functionality.